As real estate prices continue to rise and thermal regulations for new buildings are becoming more stringent, how will we be able to afford housing in the years to come? To build a house costs between 1,300 and 1,600 € per m². Imagine a system of wooden modules that allows the industrialised production of cheap housing. Ecological, foundation-free, movable and with very high energy performance, at a cost of around 750 € per m². This is the project that Gilles Guerry, inventor and architect, is currently developing.

Blockwood's objective is to build houses that meet the new thermal requirements, which are aimed at energy savings. By using simple tools, considerably reducing design and prefabrication time.

Blockwood's objective is to build houses that meet the new thermal requirements, which are aimed at energy savings. By using simple tools, considerably reducing design and prefabrication time.

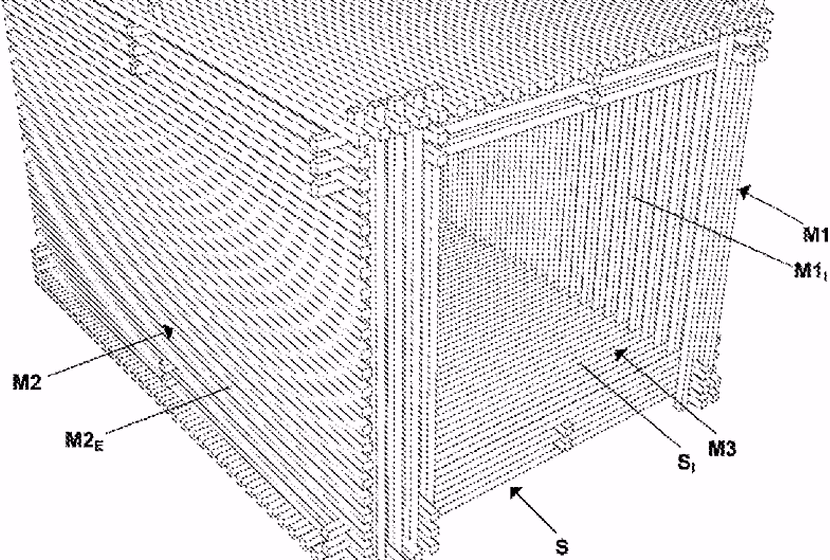

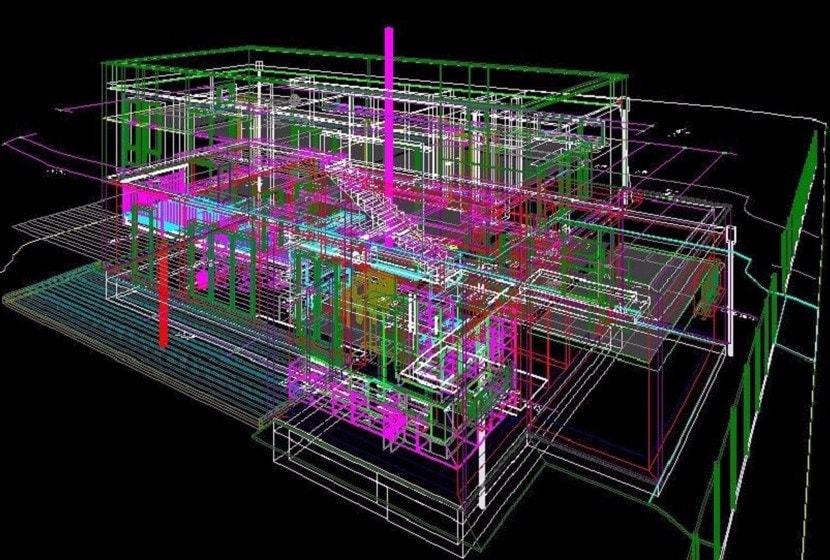

"All the parts, rafters and plates, which make up the modules, are standardised.explains Gilles Guerry. With 32 different types of parts, I shape different frames which, when put together, form stable, transportable and insulated modules. This wooden frame also acts as the exterior cladding of the house, saving time on the building site. » The architect uses 3D digital modeling for efficient pre-production. "Assembly is quick and easy, he continued. Like a great mechanic, the job site boils down to the assembly of prefabricated elements using a screwdriver. No measuring, drilling or cutting on site. A house can be built in 3 months. »

Blockwood is initially aimed at individuals wishing to build an ecological house. « We adapt the volumes of the constructions according to the implantation and the needs of the client. »

The project is in line with sustainable development and environmental protection.

The houses built consume very little energy. They are built using natural elements, including local wood. The project is socially useful, as it creates quality habitats that are accessible to the greatest number of people. "Ecology should not be a luxury"...hammers the inventor. One of Gilles Guerry's goals is also to make local businesses more competitive. "Once I have built several houses myself, I would like to develop a network of artisan carpenters under franchise, using my system. My cutting and drilling machines are cheap and thanks to the time saved with prefabrication, the craftsman becomes competitive against large groups with production lines. »

"After numerous technical developments, intellectual property studies and market research, Blockwood is now just waiting to meet the public, smiles Gilles Guerry. For a few months, the Rennes-La Novosphère organization put a plot of land at the architect's disposal, rue de Lorient. He is going to build his first large-scale prototype there by the end of April. « I had enough money to make the prototype, but not to buy a piece of land well enough to attract visitors. » The prototype will consist of 4 modules of 20 m² each. "They are intended to be linked together, but are individually autonomous. Their construction will allow me to check the production price and to house, in one of the spaces, a machine that I will use to build the other modules more quickly. »

"There is a shortfall of 800,000 homes in France, land ownership is increasing, purchasing power is falling and banks are finding it harder to lend. And as if the picture were not complex enough, the requirements in terms of energy performance and ecology reveal the unsuitability of traditional building materials and techniques.thinks Gilles Guerry.

After studying biology, this Breton, who describes himself as a "do-it-yourselfer", joined the architecture school in Rennes, then worked for two years in Odile Decq's architecture agency in Paris. « Rather than inventing complicated and expensive machines to build, let's reconsider things, use the computing power of computers and stop building as we did a hundred years ago.he says. Thanks to specific digital and production tools, Blockwood enables all stages of the construction process to be streamlined as much as possible. From custom design to assembly, we control the quality, cost and delivery time of the building. »

For more information : gilguerry@hotmail.fr / 06 70 78 59 96

(Source : Rennes-La novosphère – 2013)

{Jacuzzi on}