An American startup specializing in augmented reality, Daqri, has just developed a hologram-based 3D printing technology unveiled by the MIT Technology Review.

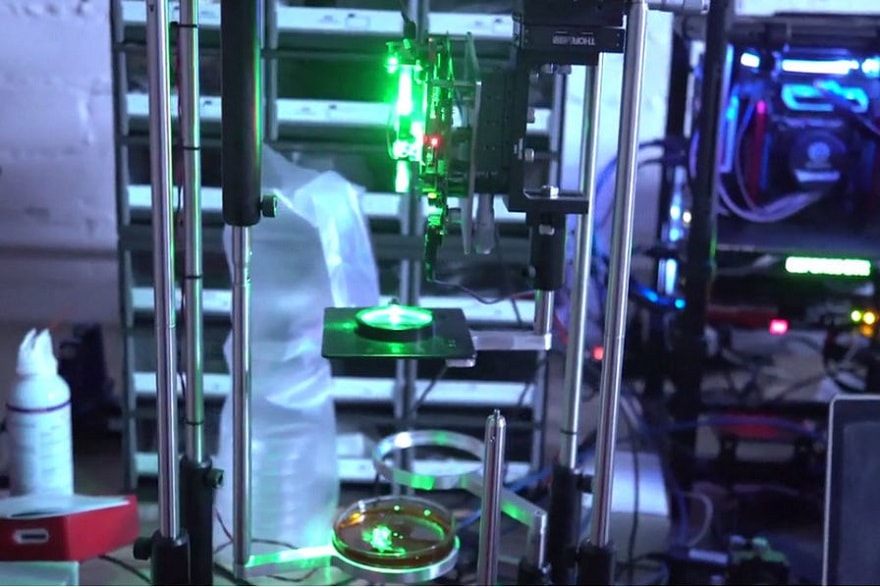

Un bright green laser flashes, immersed in a Petri dish. Out of nowhere, the shape of a paper clip emerges - ghostly at first, then solid. Five seconds later, the object is recovered, cleaned and ready for use.

The basic principle here is a 3D printing technique that uses lasers to harden a light-activated monomer plastic into a solid plastic, polymerization. But unlike other approaches, which scan a laser back and forth to create shapes one layer at a time, this system does so using a 3D light field - in other words, a hologram. Advantage: It could make 3D printing much faster.

At the heart of the device that printed the paper clip is a holographic chip developed by Daqri, a startup that designs and builds augmented reality devices from laboratories in San Francisco and Milton Keynes in the United Kingdom.

The advantage of the Daqri chip is that it can create holograms without the use of complex optical devices. On a layer of silicon, an array of adjustable crystals controls the amplitude and phase of the laser light sent to the cell. Software is used to adjust the crystals to create the interference from which the 3D "holographic" field is created.

In the experiments, the team used the chip to create solid objects by projecting holograms into containers of various monomers activated by light. It can currently make small objects, such as a paper clip, in about five seconds - a process that could take several minutes with a normal 3D printer.

Seamus Blackley, Daqri's scientific director, recognises the advantage of the object printed in this way in a single step: it no longer suffers from the shortcomings of conventional 3D printing linked to the superimposition of layers one after the other. And objects in volume should take about the same amount of time to print as smaller objects.

There are, however, certain limits. The current material only creates shallow shapes, for example, like the paper clip. But the depth is expected to increase with the size of the holographic chip used, and the company plans to increase the scale of the device accordingly.

Dávid Lakatos, product manager at 3D printing company Formlabs, says heat could also be a problem. "Polymerization is an exothermic process... (which produces heat)," he says, referring to the process by which light-activated liquid contracts into a solid. "Printing something faster means more energy in the reaction is released. "This would lead to a greater risk of melting on larger objects.

The Daqri chip also has other interesting applications. While the company is known for its augmented reality devices, it plans to use its holographic chip to create screens with multiple layers of information on cars, for example. Currently, a prototype headliner has been created that can project an image onto a windshield with a resolution equivalent to a 720p HD screen, in real time. To be continued.

(Source: MIT Technology Review - Jamie Condliffe February 17, 2017)

Login

0 Comments

Inline Feedbacks

View all comments