1 - Overview of nanomaterials applications in the automotive industry

2 - Batteries, aluminium structures, joints: the new applications for silicon nanopowders

3 - Commercial and future applications of carbon nanotubes in the automotive industry

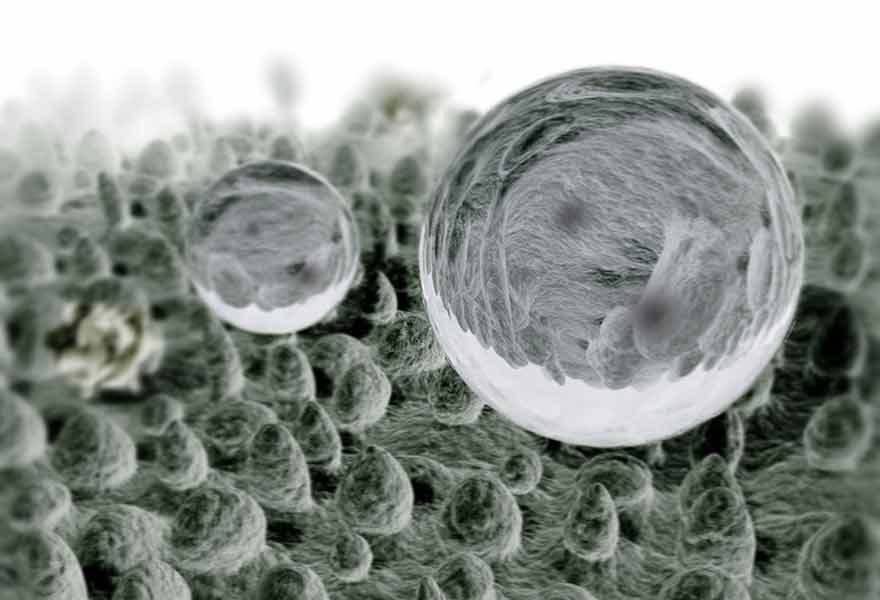

4 - Tyres and nanomaterials

5 - Road pavements (nano) in the automobile: what advantages, what advantages, what advantages? promises, what uncertainties?