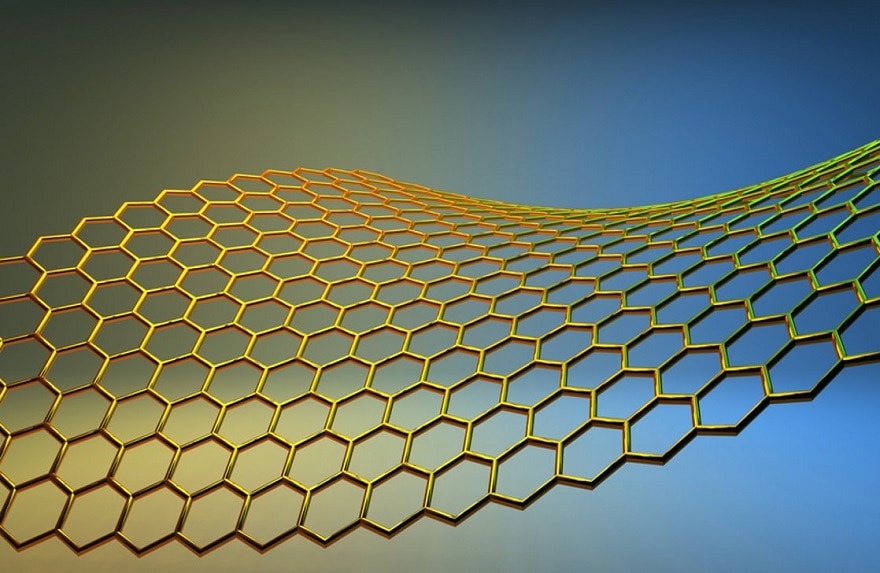

The first 2D crystal

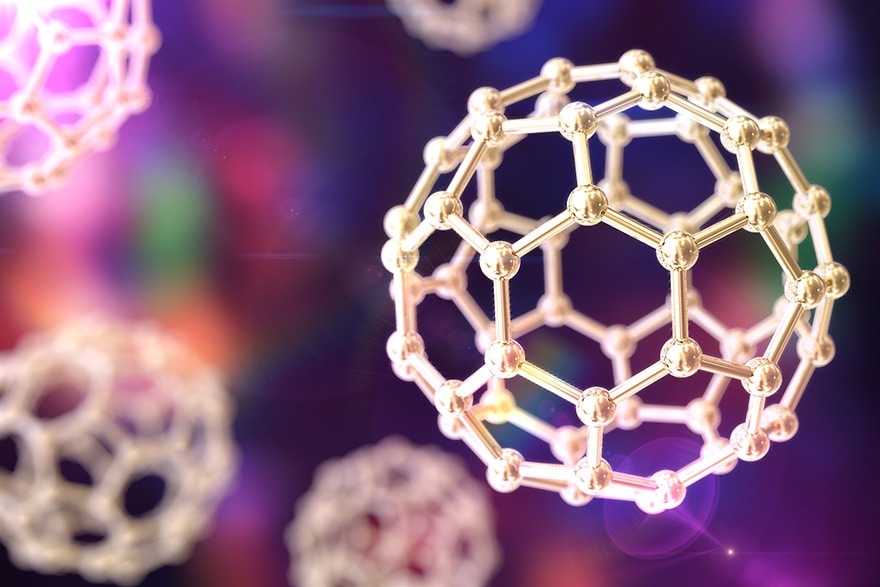

Multiple potential functions

Supercapacitors

A biocompatible and biostimulating nanomaterial

Conclusion

Anything to add? Say it as a comment.

Anything to add? Say it as a comment.

Already registered? I'm connecting

Register and read three articles for free. Subscribe to our newsletter to keep up to date with the latest news.

→ Register for free to continue reading.

You have received 3 free articles to discover UP'.