Each European country must produce 23% of its energy in renewable mode by 2020. To meet this challenge, France - as part of the energy transition law passed on 14 October - has planned an arsenal of methanisers of all kinds (digesters for manure, waste, straw, etc.), numbering a thousand. If farm anaerobic digestion plants constitute a large deposit (400 million tons of organic matter produced each year), how will canteens, collective restaurants and supermarkets be organized to meet their obligation to sort bio-waste at source?

The Mené territory is pioneer. The Bretons know it: over there, in the heart of the Côtes d'Armor, we know how to get together to play as a team. To such an extent that energy autonomy is at handy. " This is the key factor for any optimization." says Patrick Dabert, specialist from biological waste treatment to IRSTEA.

This organization, the son of the former CEMAGREF, is in charge of supporting the French effort to develop biomass. "The Geotexia plant, inaugurated in 2011 in St Gilles du Mené, illustrates the success of a dialogue between breeders, industrialists and farmers, underlines Patrick Dabert. Thanks to the commitment of 30 pig farmers, 38,000 tonnes of liquid manure, 37,000 tonnes of agri-food waste (abattoirs, greasy waste, etc.), cereal residues and poultry droppings are recovered here. This plant produces 13.8 GWh ". "Multipurpose projects resulting from a well-understood management of the common interest are rare," notes Patrick Dabert, who nevertheless believes that cooperation is the only way to make projects relevant and effective..

Inventory of biomass deposits

The methanation landscape is indeed contrasted. In France, we have about 140 on-farm methanisation plants, 9 factories treating household waste and generating biogas (in Lille, Angers, Vannes or Montpellier for example), 90 methanisation units linked to food-processing factories, and 71 of our landfills (out of the 320 in France) that collect the biogas produced by fermentation.

The methanation landscape is indeed contrasted. In France, we have about 140 on-farm methanisation plants, 9 factories treating household waste and generating biogas (in Lille, Angers, Vannes or Montpellier for example), 90 methanisation units linked to food-processing factories, and 71 of our landfills (out of the 320 in France) that collect the biogas produced by fermentation.

"It is essential to carry out inventories on the deposits to locate and calibrate the methanisers to be built." insists Patrick Dabert, whose colleague, Tina Rambonilaza, an economist in Bordeaux (IRSTEA) confirms : "a cultural revolution will be needed for people to come together to design common projects".

Design offices such as Akajoule (St Nazaire) are developing to accompany and guide the actors but it is a political governance that will be necessary to encourage coherent projects. We note that the project of the farm of a thousand cows (Picardie) is the focus of all kinds of opposition because it was set up without integrating the actors of the territory. The key is consultation, which took ten years for the breeders of the Mené to set up Géotexia and a little less for the TIPER project of Methaneo...

Let's go back in time and analyse here the reasons for the incentive to use biogas, an energy resource as old as the world. Because it has been exploited for a long time. It is even thought that the Assyrians heated their baths by burning it more than three thousand years ago... But it wasn't until the 19th century that the Assyrians began to use biogas to heat their baths.e century to build the first industrial digester in India. Proving that unnecessary organic matter can decompose to produce a usable gas. In 1896, the city of Exeter in Great Britain invented urban lighting with gas from sewage sludge.

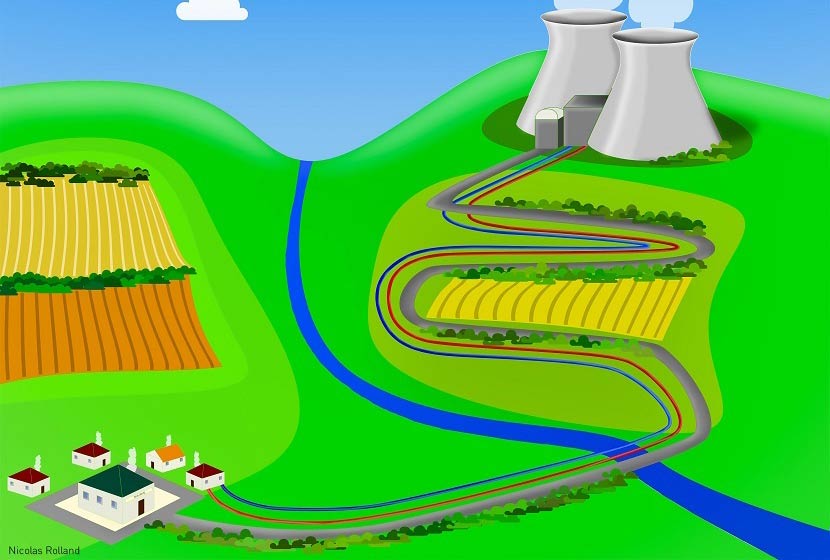

Although France had about a hundred on-farm methanisers in the 1980s, it abandoned this practice at the time of its centralized nuclear policy. Faced with the "greenhouse effect" problem, the increase in the cost of energy and the need to produce renewable energy, methanisation, i.e. the anaerobic digestion of waste, makes it possible to optimise the energy balance of the sectors. It puts into practice the circular economy by making a resource out of waste, reducing the greenhouse gas emissions (methane) that are emitted when any organic matter is stored.

The different European models

In 2010, 10.9 million tonnes of oil equivalent (Mtoe) of primary energy biogas were produced in the European Union from agricultural deposits (for more than half) but also from landfills and treatment plants. Germany alone supplies 6 Mtoe with its six thousand plants, most of them "on the farm". Its 2004 EEG Biogas law (Erneuerbare-Energien-Gesetz) provided an incentive with a feed-in tariff of 0.18 €/kWh. Criticized for using energy crops (corn silage) in co-digestion with livestock manure, the German model was followed by Austria. Denmark stands out with about twenty centralised units (in addition to more than sixty on-farm units) operating in co-digestion (such as the Geotexia plant) and bringing together farmers, communities and industries.

In 2010, 10.9 million tonnes of oil equivalent (Mtoe) of primary energy biogas were produced in the European Union from agricultural deposits (for more than half) but also from landfills and treatment plants. Germany alone supplies 6 Mtoe with its six thousand plants, most of them "on the farm". Its 2004 EEG Biogas law (Erneuerbare-Energien-Gesetz) provided an incentive with a feed-in tariff of 0.18 €/kWh. Criticized for using energy crops (corn silage) in co-digestion with livestock manure, the German model was followed by Austria. Denmark stands out with about twenty centralised units (in addition to more than sixty on-farm units) operating in co-digestion (such as the Geotexia plant) and bringing together farmers, communities and industries.

The future in France may well lie in ingenuity. That of Olivier Lespinard who wants to be pragmatic by developing a dry methanisation project (using straw) and above all modular for farms (or equestrian centres). Founder of ERIgene, Olivier Lespinard offers containers that can be filled on each farm and then brought to a biogas production centre, which is thus supplied by a network of breeders. He draws on the expertise of the process engineering team at the Université Technologique de Compiègne (UTC) and is working with the Lasalle Beauvais Institute to set up a demonstrator as part of the MEXA project (dry methanisation on a farm scale) supported by the Picardy Region and OSEO. The challenge is to design a process with automated, reliable, modular and amortizable installations as quickly as possible. For the farmer, this is a welcome additional resource...

Ademe is one of the key operators to support methanisation projects. Locally, the AILE association in Rennes - which works to develop the biogas plan in Brittany - has its work cut out for it. For farm methanisers, the manufacturers are SMEs such as Evalor, Naskéo, Armor Green, Methaneva, Fertigaz, etc. It is estimated that the cost of a methaniser is one million euros, and the installation of a methaniser can be assisted (State bonus) if the process is energy efficient and makes good use of the heat produced.

"One challenge ahead will be to find solutions in the city to deal with organic waste from shops, offices, buildings..., says Patrick Dabert. Will it be necessary to install under buildings containers like those that exist in India or China where people come to deposit their peelings and organic waste? » Nevertheless, the circular of 10 January 2012 (resulting from the Grenelle II Waste Plan), which requires sorting biowaste at source, will in 2016 be aimed at these small structures producing only 10 tonnes per year (instead of the 120-tonne threshold in 2012).

With its 1,400 employees, the Saria industries group surfs on these binding texts. Positioned in this segment of bio-waste recovery from catering, mass distribution and food processing, it has installed three methanisers in the west of France: Valdis in Pays de Loire, Biogasys and Bionerval in Vendée... to put an end to the huge waste of landfill, burial or incineration.

|

Did you say methanation? The methanation phenomenon has been known for a long time. It is the degradation of organic matter, in the absence of oxygen and protected from light, by the combined action of several groups of micro-organisms. It makes it possible to produce flammable gas (energy), and to transform waste, effluents, organic products into digestates that can be used as fertilizer. |

|

The large deposit of ...our organic waste... Today in France we produce about 400 million tons (Mt) of "organic waste" (in gross weight). Among them, there are 298 Mt of animal excreta of which 243 Mt come from cattle breeding only (IFEN - SCEES (2005). These livestock wastes have some particularities: - about half of it is lost in the fields and is not recoverable, - 2/3 of the recoverable fraction is made up of solid manure (a mixture of straw manure or wood chips, for about 106 Mt) and can only be treated alone in dry methanisation. - The majority of the production is located in the west of France within Brittany, Pays de la Loire and Normandy, leading to critical pollution problems in Brittany in particular. |

Today, most of the processes treat liquid waste, so it is necessary either to optimize waste mixtures or to develop and optimize dry methanation processes.

Dorothy Browaeys, Deputy Editor-in-Chief UP'.